Moving Heavy Industrial Equipment in Austin: Key Considerations

Over the past decade, Austin and the broader South Central Texas region have experienced rapid industrial growth. From large-scale telecommunications expansions to booming commercial construction and infrastructure upgrades, the area has evolved into a major hub for development.

With this expansion came the need to move heavy industrial equipment. Successfully moving heavy objects requires careful planning and coordination. From navigating dense construction zones to complying with local regulations, even small missteps can lead to delays, added costs or safety risks.

This blog highlights key considerations to help ensure a smooth move, no matter the size or scope of your project.

1. Know What You’re Moving

When planning an industrial move, the first step is understanding exactly what’s being transported. Different types of equipment have different requirements for handling, packaging, and delivery.

Some common examples include:

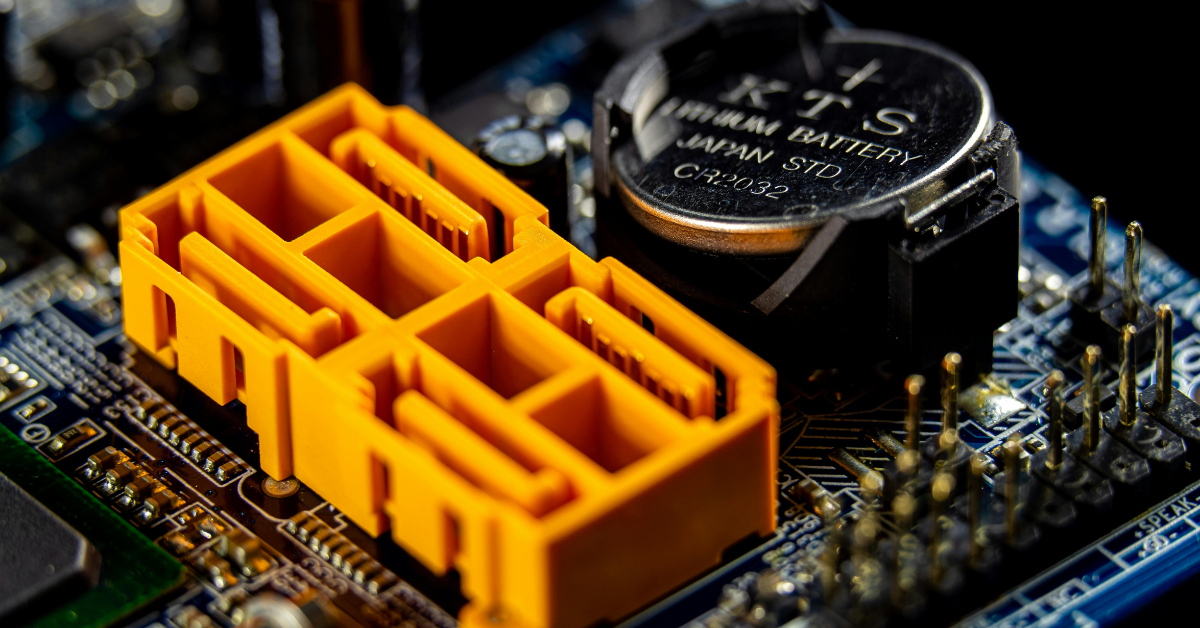

- Telecommunications equipment – Often large, sensitive and valuable; may include data center racks, cabling, antenna components or power distribution units that require careful stabilization and handling

- HVAC units – Heavy, awkwardly shaped and typically crane-lifted into position

- Medical or lab equipment – Highly sensitive and fragile; may need climate-controlled environments and careful stabilization

- Modular components – Pre-assembled structures or panels that demand wide-load handling and precise placement

- FF&E (furniture, fixtures, and equipment) – Often delivered in phases and installed in coordination with other trades

2. Review Manufacturer Guidelines Before You Move

Before planning how to handle or move machinery, take time to review the manufacturer’s instructions. Owner’s manuals often contain critical information about how to safely disconnect, disassemble or prepare machinery for transport.

Some vendors may even require a certified technician to prep or uninstall the equipment before it can be moved. Skipping this step could risk damaging the equipment or voiding a warranty.

If your team is managing the move in-house, make sure they’re fully briefed on these guidelines. Starting with the right preparation helps prevent accidents and keeps your equipment protected from point A to point B.

3. Categorize by Handling Requirements

Once the equipment has been identified, the next step is evaluating how it needs to be moved. Proper categorization ensures the right equipment, logistics and safety measures are in place from the start. Key factors to assess include:

Size and weight

These determine the type of trailer or transport vehicle needed, whether special permits are required, and what routes can accommodate the load based on bridge limits, height clearances and road restrictions.

Fragility

Fragile equipment (such as electronics or lab gear) may need custom crating, shock absorption, temperature control or careful stabilization to prevent damage during transport.

Setup complexity

Some items must be delivered and installed in a specific order or staged on-site before assembly. Complex setups can affect scheduling, staging and coordination with other trades or project phases.

4. Plan for the Site and Surroundings

Assessing the surroundings in advance is key to a safe and efficient move.

Urban job sites often involve tight spaces that limit staging, complicate access and require careful coordination around traffic patterns and time-of-day delivery restrictions. In contrast, rural areas may offer more room to maneuver but can involve unpaved roads, uneven ground conditions or longer travel distances from storage hubs.

If the delivery is heading to an active construction site or live job zone, it’s important to account for on-site hazards, ongoing work and changing access points.

Key site-specific factors to consider include:

- Staging areas: Is there a safe and accessible space to store equipment before installation?

- Unloading zones: Can trucks and trailers be positioned safely for offloading?

- Crane or lift access: Will you need vertical equipment or rigging to move items into place?

5. Understand Local Regulations and Permits

Moving heavy loads often means navigating a complex web of state and local regulations, especially when loads exceed standard dimensions or weight limits.

In Texas, oversize and overweight permits are issued by the Texas Department of Motor Vehicles (TxDMV). These permits are required for loads that exceed legal limits for height, width, length or weight, and they often come with specific restrictions on travel times, routes and escort vehicle requirements.

At the municipal level, many deliveries—particularly in urban areas—fall under Right of Way (ROW) regulations, which govern access to public roads, sidewalks and curbs. These rules may limit delivery hours, require prior approval or mandate traffic control measures to prevent disruption in high-traffic zones.

6. Coordinate the Full Supply Chain (Not Just the Delivery)

Instead of focusing solely on final delivery, it’s important to manage the full supply chain from start to finish. This includes everything from storage to timing to contingency planning. Key elements to consider:

Warehousing

Temporary storage may be needed to hold equipment until the job site is ready. This provides flexibility when schedules shift and helps protect valuable materials from exposure or damage.

Inventory staging

Large projects (such as data center construction or hospital expansions)often unfold in phases. Planning deliveries around each stage prevents bottlenecks and allows crews to install equipment as soon as it’s needed.

Weather and site access

In Texas, heat, storms, or flooding can impact road conditions and job site readiness. Monitoring forecasts and having backup routes or rescheduling options can minimize costly disruptions.

Equipment and crew availability

Ensure that cranes, rigging tools and skilled operators are lined up ahead of time, especially during peak construction seasons. Limited availability can delay critical lifts or require rescheduling of related trades.

7. Prioritize Safety and Specialized Handling

When moving heavy machinery or equipment, safety is non-negotiable. These moves often involve large, expensive and sometimes hazardous items that require specialized tools and experienced crews to handle them correctly. Key safety and handling considerations include:

Rigging, strapping and lifting equipment

Equipment such as cranes, machine skates, forklifts, spreader bars, toe jacks and other machine-moving equipment must be matched to the weight and dimensions of the load. Improper lifting techniques or under-rated gear can cause costly accidents and injuries.

Trained and certified teams

Personnel involved in the move should have up-to-date training and certifications in equipment handling, load securing and safety compliance. Having the right people on the job ensures tasks are done correctly and within regulatory standards.

Documentation

Every move should be fully documented and properly insured. This includes bills of lading, condition reports and risk assessments. In the event of damage or delay, having complete paperwork can simplify claims and help protect everyone involved.

8. Work With the Right Partners

The ideal way to move industrial equipment is by partnering with professionals who specialize in machinery moving and heavy equipment logistics. Experienced vendors understand the unique challenges of the region and are equipped to navigate everything from permitting and traffic to site access and unpredictable weather.

Smooth coordination between carriers, contractors and site supervisors is essential. Clear communication helps prevent delays and ensures that each phase of the move runs according to plan. Partners with local knowledge and a proactive mindset can spot potential issues early, navigate regulations with ease and provide timely updates throughout the process.

If you’re looking for support in the Austin area, The Armstrong Company has the local expertise and coordination experience to handle complex industrial moves from start to finish.

Moving Big Equipment in a Fast-Growing Market

As Austin continues to grow, so does the need for smart, efficient logistics. Moving heavy industrial equipment in this environment is absolutely doable, but it requires careful planning, clear communication and a strong understanding of the entire supply chain.

From warehousing and staging to permitting, transport and on-site delivery, every step matters. Success depends on managing the full process.

If you’re planning a complex move in the Austin area, Armstrong can help coordinate and execute every detail. With the right team and logistics solutions in place, your project can move forward safely, efficiently and right on schedule.