Seasonal Challenges Faced with Climate-Controlled Warehousing

Climate-controlled warehousing is essential for storing temperature-sensitive goods. However, managing these facilities comes with its own set of challenges, especially as the seasons change. Fluctuating temperatures, rising energy costs and humidity control issues can all impact warehouse operations.

In this blog, we’ll explore the seasonal challenges faced by businesses in managing climate-controlled warehouses, and offer insights into strategies and technologies that can help mitigate these issues. Let’s dive in!

What is Climate-Controlled Warehousing?

Climate-controlled warehousing refers to storage facilities that maintain specific environmental conditions—such as temperature, humidity and air quality—designed to protect sensitive products. These warehouses are essential for goods that require strict climate control to preserve their quality, safety and functionality throughout storage and transit.

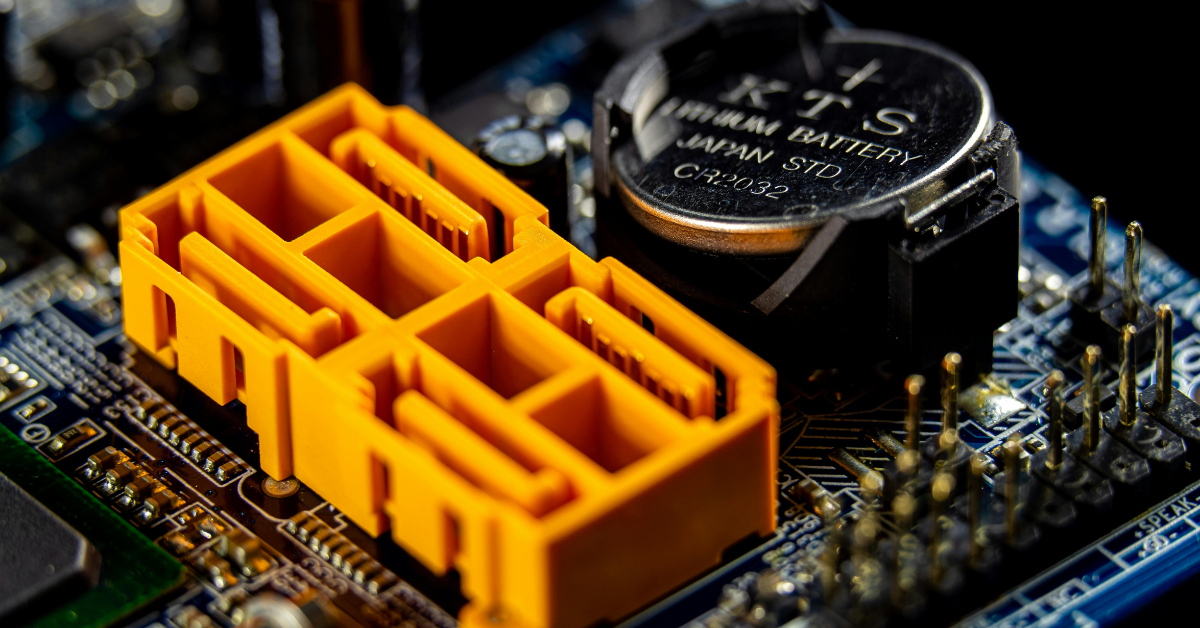

Products like food, beverages, pharmaceuticals and electronics are prime examples of items that benefit from climate-controlled environments.

To achieve these conditions, warehouses use advanced systems that regulate temperature and humidity levels, ensuring a stable environment year-round. These temperature-controlled facilities are equipped with insulation, cooling, heating and humidity control systems to create the ideal storage conditions for various products.

Seasonal Challenges in Managing Climate-Controlled Warehousing

Climate-controlled units present unique challenges that evolve with the changing seasons. Fluctuating temperatures, varying humidity levels and increased energy consumption are just a few of the seasonal hurdles businesses face. Let’s dive into the specific challenges that arise throughout the year.

1. Seasonal Temperature Fluctuations

Temperature fluctuations throughout the year present significant challenges for climate-controlled warehousing. In winter, colder temperatures increase heating demands, while in summer, higher temperatures raise cooling requirements, both putting strain on systems. These hot and cold extremes make it difficult to maintain a consistent internal temperature, affecting sensitive products like perishables and pharmaceuticals, potentially shortening their shelf life and leading to spoilage, loss of efficacy or degradation.

2. Energy Consumption and Costs

Energy consumption is a major concern in climate-controlled warehousing, particularly during peak seasons. In winter, heating systems use more energy, and in summer, cooling systems work harder, raising costs. These increased energy demands can significantly impact operational budgets, especially when trying to maintain optimal conditions for sensitive goods.

3. Humidity Control Issues

Maintaining proper humidity levels is a challenge, especially with seasonal changes in outdoor humidity. Low humidity in winter can dry out products, while high humidity in summer can cause mold growth and product spoilage. Fluctuations in humidity can damage goods, particularly in industries where precise environmental conditions are critical, such as pharmaceuticals and food storage.

4. Managing Capacity

Balancing storage capacity during peak and off-peak seasons is another significant challenge for climate-controlled warehouses. During low-demand periods, warehouses may have excess space, leading to underutilized resources and inefficiencies. On the other hand, during peak seasons, the demand for climate-controlled storage can exceed available space, resulting in missed opportunities or delays in service.

5. Supply Chain Complexity

Managing a climate-controlled supply chain requires coordinating a network of stakeholders, including suppliers, transporters and warehouse operators. As seasonal conditions shift, it can be challenging to ensure that each party adapts their processes specifically to the changing environmental conditions for temperature-sensitive goods. Inconsistent procedures and lack of synchronization can disrupt the ideal temperature range, potentially compromising product quality.

6. Supply Chain Disruptions

Seasonal weather events like winter storms and summer heatwaves can disrupt transportation and inventory management. Delays in shipments can lead to backlogs, further complicating the task of keeping products on schedule. These disruptions create additional challenges in maintaining timely delivery and protecting the integrity of sensitive goods.

7. Labor and Maintenance Planning

During peak demand periods, resourcing allocation becomes a key challenge for climate-controlled warehouses. These busy seasons often require additional staff and resources, but balancing the right levels of support can be difficult, leading to inefficiencies. Additionally, the frequency of maintenance tasks may vary depending on the season, with more frequent checks needed during high-demand times to ensure that systems are functioning optimally.

Strategies for Overcoming Seasonal Challenges

Managing climate-controlled warehouses through seasonal shifts requires a proactive approach. Here are five key strategies to help businesses overcome seasonal challenges and maintain efficient operations:

- Seasonal Planning and Forecasting: Accurate forecasting helps warehouses anticipate peak demand periods, allowing businesses to adjust storage capacity, staffing levels and maintenance schedules in advance. This ensures optimal resource allocation and minimizes both underutilization and overcapacity.

- Flexible Resourcing and Labor Management: During high-demand seasons, flexible staffing models—such as temporary workers or cross-trained staff—help ensure that warehouses have enough support. Additionally, leveraging technology to streamline tasks can address labor gaps and keep operations running smoothly.

- Energy-Efficient Solutions: Investing in energy-efficient, advanced climate control systems helps manage seasonal fluctuations in heating and cooling demands. By implementing systems that automatically adjust to changing conditions, businesses can maintain optimal storage conditions while reducing energy consumption.

- Outsourcing to 3PLs: Outsourcing to third-party logistics providers (3PLs) can help businesses optimize operations and reduce overhead. Partnering with a 3PL offering temperature-controlled warehouse services allows businesses to tap into specialized expertise and advanced technology without large in-house investments. This is especially beneficial during peak seasons, when demand for storage and labor is high, ensuring efficient scaling and optimal storage conditions.

Technological Solutions for Seasonal Challenges

Advancements in technology are significantly improving how climate-controlled warehouse systems handle seasonal challenges. Key innovations include:

Automated Climate Monitoring

These systems use sensors for humidity, air quality and temperature monitoring across the warehouse. Automated climate systems often integrate all three components for real-time environmental control. Here’s a breakdown of each:

- Temperature Control Systems: These systems monitor and adjust the warehouse temperature to maintain a consistent and optimal environment, reducing the risk of spoilage or product degradation.

- Air Quality Control Systems: These systems track and manage the air quality by removing pollutants, dust and airborne contaminants to ensure a clean environment for sensitive goods.

- Humidity Control Systems: These systems regulate humidity levels to prevent issues like mold growth, product shrinkage or moisture damage.

IoT Integrations

The Internet of Things (IoT) enables seamless integration of various systems within the warehouse, from climate control to inventory management. IoT-connected devices provide real-time data, allowing warehouse operators to monitor environmental conditions and make adjustments remotely. This integration also supports predictive maintenance, ensuring systems are running efficiently and reducing downtime during peak seasons.

Blockchain for Supply Chain Transparency

Blockchain technology offers a secure, transparent way to track temperature-sensitive goods throughout the supply chain. By providing a tamper-proof, real-time record of conditions from origin to destination, blockchain enhances collaboration between stakeholders and ensures that products remain within required environmental standards, reducing the risk of non-compliance or spoilage.

How The Armstrong Company Supports Temperature-Controlled Warehousing

At Armstrong, we understand the complexities of managing temperature-controlled warehousing and the challenges that come with seasonal changes. Our tailored logistics and warehousing solutions ensure your temperature-sensitive products are stored and transported safely year-round. Here’s how we support your business:

- Advanced Technology: We use cutting-edge climate monitoring and automated control systems to maintain optimal temperature, ensuring your products remain in ideal conditions despite seasonal fluctuations.

- Customized Solutions: Our team works with you to design temperature-controlled storage solutions tailored to your specific needs, whether for pharmaceuticals, food, electronics or other sensitive goods.

- Compliance Assurance: We keep your warehouse operations compliant with seasonal regulations, helping you adapt to regulatory changes and avoid penalties.

- Refrigerated Transportation Solutions: Armstrong offers reliable refrigerated transportation services, ensuring your climate-sensitive stock is safely transported, maintaining the required conditions throughout the journey.

By partnering with Armstrong, you gain access to expert solutions that optimize temperature-controlled warehousing and refrigerated transportation, keeping your inventory safe and operations running smoothly year-round.

Stay Ahead of Seasonal Challenges with Armstrong

Managing climate-controlled warehousing requires careful planning and adaptation to seasonal changes. Innovation and technology, including climate monitoring, automated systems and refrigerated transportation, are key to maintaining optimal conditions year-round.

For expert support in managing climate-controlled warehousing, contact Armstrong today. Our tailored solutions and advanced technology will ensure your inventory stays safe and compliant throughout the year.