5 Reasons to Outsource Your Warehousing Operations

Key Takeaways:

- Outsourcing warehouse operations allows businesses to scale without building costly infrastructure.

- Partnering with a 3PL like Armstrong provides access to experienced teams, advanced technology and nationwide networks.

- Streamlined processes reduce inefficiencies and free your team to focus on growth.

- Outsourcing minimizes operational risks and lowers overhead costs.

- Warehouse outsourcing is ideal for companies facing seasonal demand, labor shortages or rapid expansion.

What do large Fortune 500 companies, mid-sized manufacturers and small seasonal retailers all have in common? They all benefit from the expertise of third-party logistics providers.

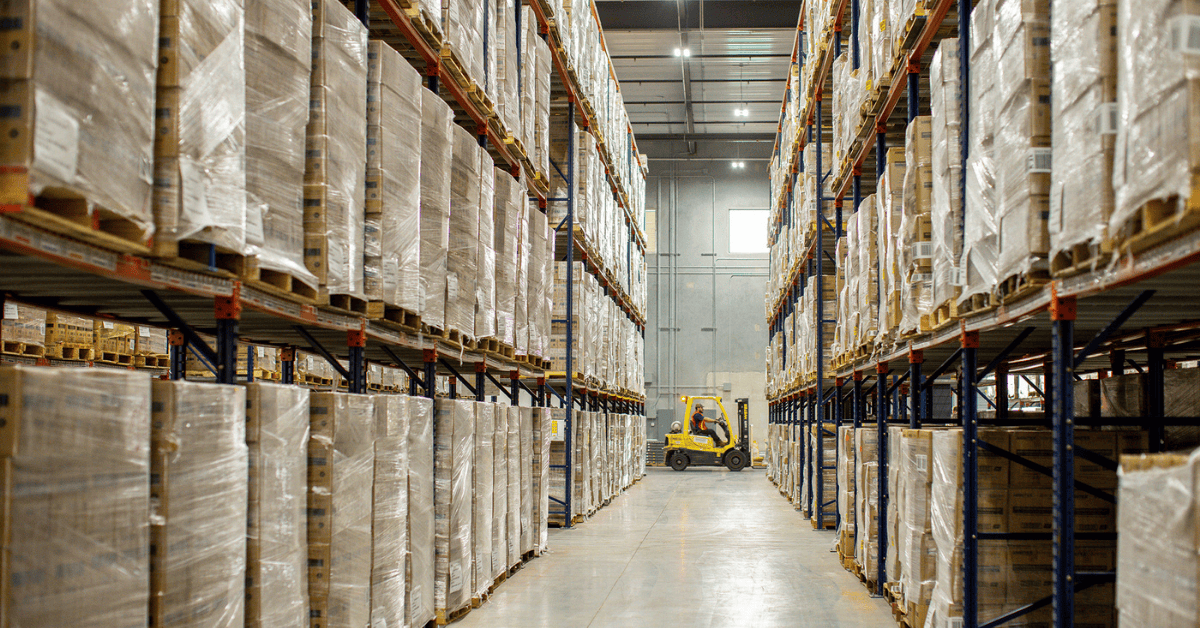

Third-party logistics providers — or 3PLs for short — exist to simplify your supply chain. Many companies don’t have the infrastructure, personnel, oversight or time to handle their own warehousing and logistics, so instead, they outsource those processes to a 3PL.

A successful outsourcing partnership can help a company reduce overhead costs while preparing to scale. For example, a manufacturing company may depend on a 3PL to receive, store, organize and transport its raw materials. Or an e-commerce company specializing in holiday decorations may call on a 3PL to help it manage the seasonal fluctuations in demand.

However, opening up your company to a third party may not be an easy decision. If you are deciding whether outsourcing your warehousing is a good fit for your business, here are five reasons to consider.

What is outsourcing warehouse operations?

Outsourcing warehouse operations means partnering with a 3PL provider to manage storage, inventory handling, fulfillment and distribution. Companies choose warehouse outsourcing when they lack the space, labor or systems to operate efficiently in-house. Armstrong supports businesses by providing scalable facilities, trained labor and proven logistics processes that streamline the entire supply chain.

Benefits of outsourcing warehouse operations

Outsourcing gives companies predictable costs, fewer operational risks and access to experienced warehouse teams. With Armstrong, businesses gain professional inventory control, nationwide capacity and real-time technology that simplifies decision-making. This allows leaders to shift their focus from daily operations to growth and strategy.

Reasons to outsource warehouse operations

1. Growth Without Guesswork

Building your own infrastructure for warehousing and fulfillment requires a lot of trial-and-error. Consequently, the learning curve can lead to losses in money, productivity and efficiency. A 3PL, on the other hand, has already been perfecting its systems for decades, and you gain access to that expertise as soon as you outsource your processes. The right partner can help you scale rapidly while maintaining flexibility within your business model.

2. Mutually-Beneficial Partnership

The best 3PLs will have the same goals as you — to grow your business. A fresh set of eyes can help identify weaknesses within your processes and present strategies to achieve your growth goals faster. In a strong partnership, your provider will seamlessly integrate into your organization, giving you the insights and manpower you need to succeed.

3. Streamlined Processes

A 3PL can handle every step of your warehousing and fulfillment, from receiving shipments to delivering products to a customer’s doorstep. For example, The Armstrong Company provides kitting services to streamline the processes within a manufacturing warehouse by taking care of storage, production, packaging and delivery. By outsourcing your operations to a single provider, you can be more productive and your business can be more efficient.

4. Sophisticated Technology

To stay ahead of your competitors, you need to be up-to-date with the latest trends and technology. Your logistics provider can help with both. At Armstrong, we provide our partners with proprietary inventory-management technology that allows them to receive minute-by-minute information about their assets from any location. With our 24-hour monitored security, leaders know their products are safe and protected.

5. Nationwide Networks

3PLs can easily manage large projects that require expansive warehouse networks. For example, outsourcing to Armstrong gives you access to a of owned locations and vetted partners. We can handle a project of any size or scale, giving you the freedom to return to your day-to-day work.

Is outsourcing right for you?

If you’re ready to take your company to the next level, give Armstrong a call at 800-288-7396.

Frequently Asked Questions

Is it a good idea to outsource warehouse operations?

Outsourcing is beneficial when you need expert logistics support, scalable space or lower operational costs. Armstrong helps businesses reduce overhead while improving service levels and supply chain visibility.

What are the advantages of warehouse outsourcing?

Key advantages include predictable pricing, reduced labor management, access to advanced technology and faster scaling. Armstrong also offers secure facilities and nationwide capacity to support long-term growth.

What does a warehouse outsourcing company do?

A warehouse outsourcing company handles storage, inventory control, order fulfillment, packaging and transportation. Armstrong integrates these services into one streamlined solution so businesses can operate more efficiently.

Who should outsource their warehouse operations?

Companies that experience rapid growth, seasonal spikes, limited space or staffing challenges benefit the most. Armstrong supports Fortune 500s, manufacturers, retailers and ecommerce brands that need reliable, flexible logistics support.